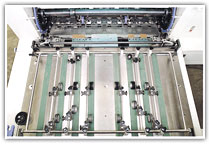

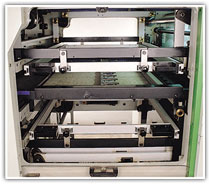

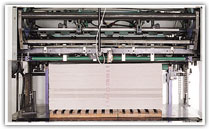

| 》Diecutting & Stripping Machine BD-1050CS >> Machinery Introduction

|

||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||

| 寶德企業股份有限公司 Baoder Enterprise Co.,Ltd. COPTRIGHT c 2008 BAODER Enterp |

| 338桃園市蘆竹區長興路三段37號 NO.37,Section 3,Changxing Road,Luzhu District, Taoyuan City ,Taiwan TEL:886-3324-8933 FAX:886-3324-6333 |